As companies in the industrial chemical, oil and gas, and petrochemical sectors strive to achieve sustainability and ESG goals, they should consider the current state of their supply chain and how it can contribute to their goals in a meaningful way.

In this blog, we’ll dive into supply chain circularity, the benefits, and how we can guide you from a wasteful, single-use approach to a packaging strategy that supports a circular economy.

What is a Circular Supply Chain?

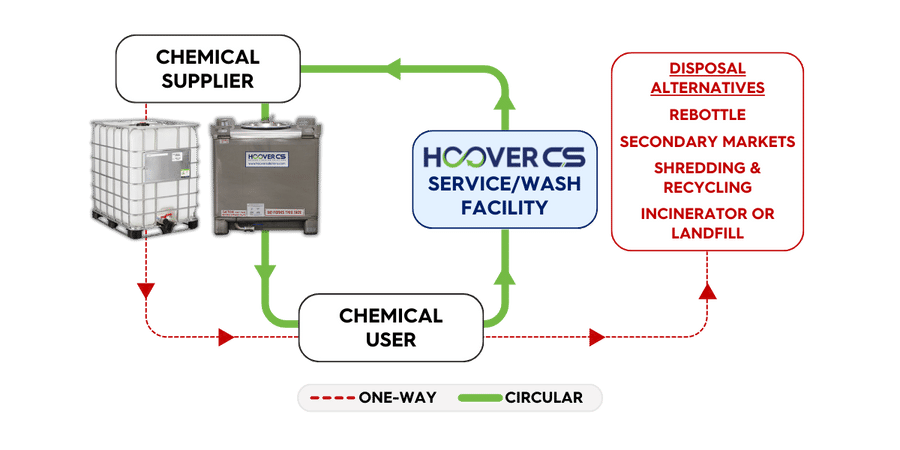

A circular supply chain is designed to minimize waste and maximize the use of resources. This is accomplished by keeping products and materials in use for as long as possible, recycling when no longer needed, and/or repairing or reconditioning where possible to extend their useful life.

In contrast, a traditional linear supply chain is designed to extract resources, manufacture products, and then dispose of them once they are no longer needed. This linear model creates an alarming amount of waste and pollution and is not sustainable in the long term.

Benefits of a Circular Supply Chain

- Reduced waste: With products and materials in use for as long as possible, this can lead to a significant reduction in what ends up in landfills and incinerators.

- Less pollution: Recycled, refurbished, and reconditioned products have a lower environmental impact than manufacturing something new, which reduces Scope 1, 2 and 3 emissions.

- Improved efficiency: By improving the utilization rate of existing products through extending their useful life, you’re able to streamline operations and reduce downtime.

- Increased profits: By reducing costs and improving efficiency, new revenue opportunities can be realized.

Implementing Circularity within Your Supply Chain

One way to implement circularity within your supply chain—especially for the storage and transportation of bulk liquids, chemicals, catalysts, and other materials—is to transition to reusable containers that are built to last for 25 years or longer. Each year, tens of millions of single-use and one-way containers are produced, used once, and then disposed of – whether shredded and recycled or sent to an incinerator or landfill.

A strong packaging partner will be able to analyze your container fleet, helping you understand if you have the right mix of tanks and containers, as well as sizes. Additionally, that partner should be able to support your tanks with the full range of integrity services needed to ensure the shelf-life of each tank.

Like other circular solutions, reusable IBCs require producers or their customers to facilitate a return leg. Hoover CS addresses this through asset tracking technology that provides its customers with visibility on the location of their IBC fleet, enabling them to optimize their use and return.

Additionally, when you rent a tank or container from us, you gain access to our network of company-owned and third-party Service Centers, which provide services such as IBC wash, repairs, reconditioning, and more.

Our team of packaging experts coordinates applicable tank services, transportation to-and-from your facilities, and even provides logistical support to ensure your tanks are delivered on time, minimizing operational disruptions while simultaneously maximizing value.

If you’re ready to improve your supply chain circularity by making the switch to sustainable tanks with Hoover CS, contact us today and show the world how you create more value with less waste—it’s an impact for good on your company’s future and our world’s.