The packaging sector, particularly in chemicals and catalysts, faces pressure to innovate as industries worldwide pivot towards sustainability. Looking ahead at the future of sustainable industrial packaging, we anticipate advancements in how we define environmental responsibility in the sector. Keep reading to discover our findings.

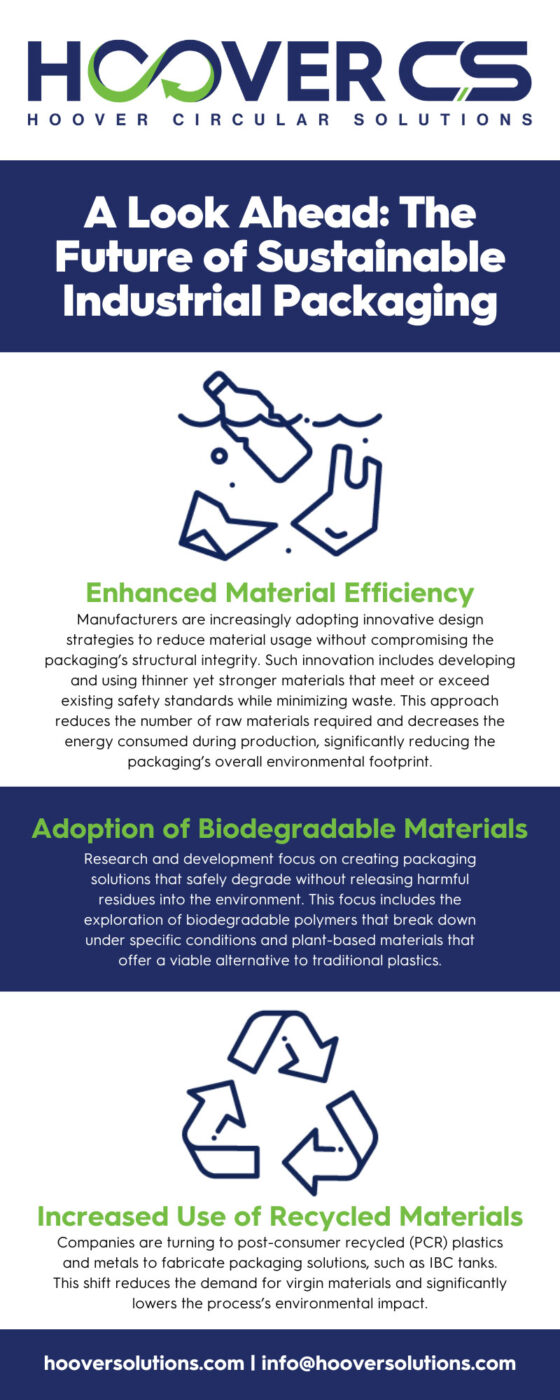

Enhanced Material Efficiency

Manufacturers are increasingly adopting innovative design strategies to reduce material usage without compromising the packaging’s structural integrity. Such innovation includes developing and using thinner yet stronger materials that meet or exceed existing safety standards while minimizing waste. This approach reduces the number of raw materials required and decreases the energy consumed during production, significantly reducing the packaging’s overall environmental footprint. Companies can cut costs and appeal to eco-conscious consumers and regulators looking for greener packaging solutions by optimizing their material use.

Adoption of Biodegradable Materials

The trend toward sustainability has spurred significant interest in biodegradable materials within the chemical and catalyst packaging sectors. Research and development focus on creating packaging solutions that safely degrade without releasing harmful residues into the environment. This focus includes the exploration of biodegradable polymers that break down under specific conditions and plant-based materials that offer a viable alternative to traditional plastics. These innovations aim to replace persistent materials that contribute to long-term pollution, particularly in landfill and marine environments, thus aligning packaging practices with global sustainability goals.

Increased Use of Recycled Materials

The future of sustainable industrial packaging also sees an increased use of recycled materials. Companies are turning to post-consumer recycled (PCR) plastics and metals to fabricate packaging solutions, such as IBC tanks. This shift reduces the demand for virgin materials and significantly lowers the process’s environmental impact. Using recycled materials also supports the circular economy model, which is vital for long-term sustainability—as well as the UN Sustainable Development Goal 12: Responsible Consumption and Production.

Development of Reusable Packaging Systems

Reusable packaging systems are becoming a cornerstone of sustainable industrial packaging strategies, especially in sectors dealing with bulk materials, such as chemicals. For example, manufacturers designed reusable IBCs for multiple uses without compromising the safety and integrity of the products they hold. Reusable containers significantly reduce the need for single-use packaging, decreasing waste and encouraging a shift toward more sustainable logistics practices.

Enhanced Durability and Longevity

The industry is enhancing the durability and longevity of containers to support the move toward reusable packaging. By developing advanced materials and manufacturing techniques, packaging, such as IBC tanks and chemical totes, can withstand the rigors of extended use and repeated cleaning cycles. These enhancements not only make economic sense but ultimately reduce environmental impact by eliminating frequent container replacements.

Smart Packaging Technologies

Incorporating smart technologies into industrial packaging is on the rise. These technologies include sensors and indicators that can monitor conditions such as temperature, humidity, and chemical levels in real-time, ensuring the safe transport and storage of sensitive materials. Smart packaging helps prevent accidents and product loss, which in turn reduces waste and enhances safety.

Minimized Transportation Impact

A significant aspect of sustainable packaging involves minimizing the impact of transportation. Designing packaging that is stackable and modular helps optimize space in shipping containers and trailers, reducing the number of trips required to transport the same amount of material, if not more. These designs cut down on emissions and reduce transportation costs.

Regulatory Compliance

Packaging solutions must adapt to meet evolving standards as environmental protection regulations tighten. Stricter regulations that mandate reductions in businesses carbon footprints, greenhouse gas emissions and waste, will likely shape future developments. Packaging designs will need to be innovative and compliant, pushing companies to actively seek greener alternatives.

Transparency and Traceability

Transparency and traceability are becoming increasingly important as business leaders and regulators alike demand clearer insights into the lifecycle—from production to disposal—and the impacts of chemical and catalyst packaging. Harnessing digital technologies for transparent, verifiable data collection will drive operational excellence within the industrial packaging sector.

Collaboration Across Supply Chains

Achieving sustainability in packaging requires collaboration across the entire supply chain. Manufacturers, suppliers, distributors, and end-users must collaborate to develop standards and practices that promote sustainability. This collaborative approach can lead to innovations in recycling, technologies, logistics, and materials management that benefit all stakeholders.

Greater Focus on Lifecycle Assessments

Lifecycle assessments (LCAs) are critical tools in measuring the environmental impact of packaging solutions. More companies will use LCAs in the future to guide their packaging strategy development by identifying areas of improvement to reduce environmental impact, such as scope 3 emissions. These LCAs could lead to significant shifts in materials used, production processes adopted, and recycling practices implemented.

Increased Education and Engagement

Stronger education and engagement with stakeholders and decision-makers on the importance of sustainable supply chain packaging is increasingly crucial. Suppliers of reusable containers, such as stainless-steel IBC totes, will need to advocate for their use within the chemical and catalyst sector, ensuring decision-makers are engaged and have the data to embrace the adoption of sustainable packaging in support of a circular economy.

Innovations in Chemical Resistance

The demand for materials that can safely interact with chemicals without degrading is driving innovation. Researchers are developing new composites and bio-based polymers that offer high resistance to corrosive substances while being environmentally friendly. These materials must contain and protect their contents and withstand the rigors of transportation and storage without releasing harmful substances into the environment. Advances in nano-coatings and barrier technologies also offer promising enhancements, improving the safety and sustainability of packaging without compromising performance.

Integration With Circular Economy Models

The future of industrial packaging integrates deeply with circular economy models, which is an approach that emphasizes the reuse and recycling of materials at the end of their life cycle. Embracing circular packaging solutions should be top priority for industries with a heavy reliance on single-use and/or one-way packaging. These industries must focus their efforts on utilizing packaging that they can easily refurbish, repurpose, or recycle.

Looking ahead, the future of sustainable industrial packaging will respond to environmental challenges and offer substantial improvements in efficiency and safety, especially in the realms of chemical and catalyst packaging. Consider how your company can integrate these trends into business practices that enhance sustainability, circularity, and operational efficiency within your organization.