Intermediate bulk containers, commonly known as IBCs, are essential in various industries for storing and transporting bulk materials. These versatile containers offer numerous advantages, making them popular across diverse sectors. Read on to find out 12 reasons you’d want to use intermediate bulk containers.

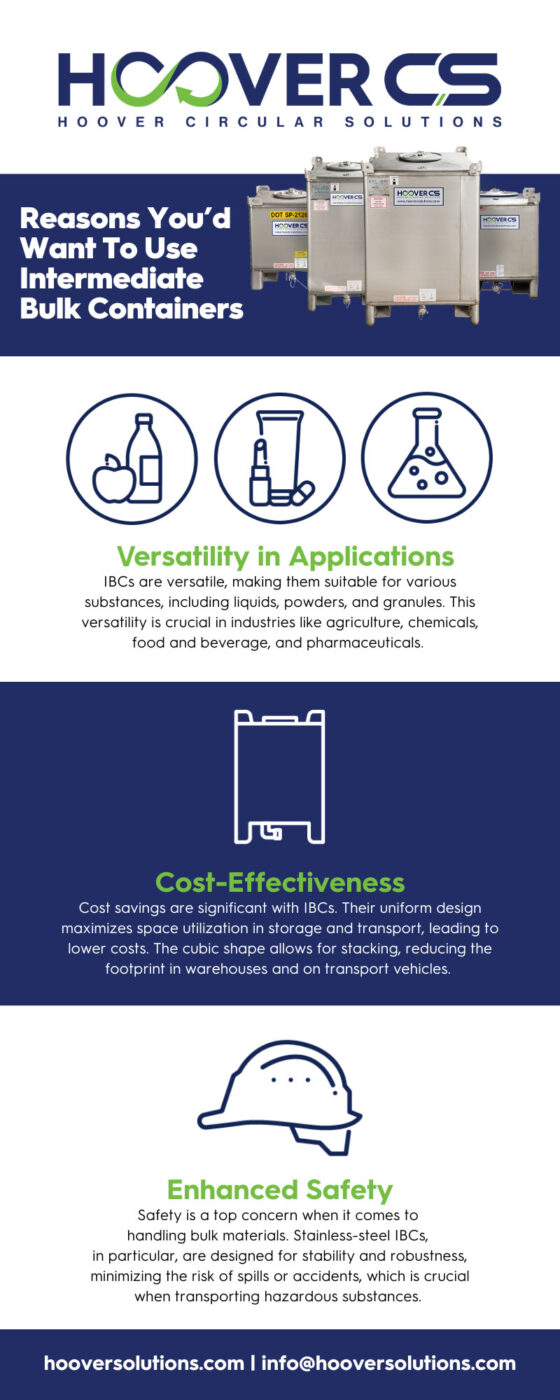

Versatility in Applications

IBCs are versatile, making them suitable for various substances, including liquids, powders, and granules. This versatility is crucial in industries like agriculture, chemicals, food and beverage, and pharmaceuticals. IBCs can handle everything from hazardous chemicals to consumable products, ensuring safe and efficient storage and transportation. Their adaptability to different materials and sectors makes them indispensable in the global supply chain.

Cost-Effectiveness

Cost savings are significant with IBCs. Their uniform design maximizes space utilization in storage and transport, leading to lower costs. The cubic shape allows for stacking, reducing the footprint in warehouses and on transport vehicles. Additionally, the durability of IBCs means a longer lifespan and fewer replacements, offering long-term cost benefits. These savings are vital for businesses looking to optimize their operations economically.

Enhanced Safety

Safety is a top concern when it comes to handling bulk materials. Stainless-steel IBCs, in particular, are designed for stability and robustness, minimizing the risk of spills or accidents, which is critical when transporting hazardous substances. Their reliable construction ensures safe containment, protecting both handlers and the environment. This aspect is particularly important for businesses prioritizing workplace safety and environmental responsibility.

Environmental Sustainability

In an era focusing on sustainability, stainless-steel IBCs offer an eco-friendly solution due to their long useful life, reusability, and ability to be responsibly recycled. Utilizing reusable IBCs significantly reduces the reliance on single-use containers, which helps minimize waste and promote a circular economy. As businesses become more environmentally conscious, reusable stainless-steel IBCs stand out as a sustainable choice for bulk material handling.

Improved Storage Efficiency

Storage efficiency is enhanced with IBCs. Their stackable design ensures optimal use of vertical space in warehouses. This is particularly beneficial for businesses with limited storage areas, as it maximizes space without expanding the physical footprint. Storing more product in a smaller area is a key advantage for companies looking to streamline their storage solutions.

Ease of Use

IBC containers are designed with the user in mind. Features like integrated pallet bases or forklift pockets make them easily movable with standard equipment like forklifts and pallet jacks, streamlining the handling process. This ease of use enhances operational efficiency and reduces labor costs and the time required for handling, making them a practical choice for businesses seeking to improve their operational workflows.

Reduced Contamination Risk

For industries with product purity requirements, such as food and pharmaceuticals, IBCs offer a significant advantage. Their closed systems minimize exposure to contaminants, maintaining the integrity of sensitive products. This factor is vital for businesses where even minor contamination can have significant implications, so IBCs ensure product quality and optimize handling safety.

Customization Options

Customization is a significant benefit of IBCs. They can be modified with various fittings like valves, lids, and liners, and a variety of parts and accessories are also available, including insulated jackets, site glass level gauges, and more. This adaptability ensures that IBCs can meet the unique requirements of different products and processes, making them a flexible solution for businesses with specialized needs.

Custom identification options are also available, such as color coding, labeling, and branding. These modifications aid in easily identifying contents, streamlining inventory management, and enhancing brand visibility during transportation and storage.

Regulatory Compliance

Compliance with regulatory standards is a top priority for many businesses, especially those handling hazardous materials. IBCs are designed to meet strict industry standards and regulations, ensuring safe and legal transportation and storage of various substances. This compliance minimizes the risk of penalties and legal issues, safeguarding a company’s reputation and financial stability. By using IBCs, businesses can confidently navigate the complex landscape of industry regulations, focusing on growth and development without compliance concerns.

Space Optimization in Transport

Transportation efficiency is a critical aspect of logistics and supply chain management. IBCs are instrumental in optimizing space in transportation vehicles due to their uniform and square-shaped design. They can be neatly arranged to maximize the use of space in trucks and shipping containers, allowing more products to be transported in a single trip. This leads to reduced transportation costs, fewer trips, and a lower carbon footprint. For businesses looking to enhance logistics efficiency while reducing environmental impact, IBCs offer an effective solution.

Improved Product Shelf Life

Product longevity is crucial in many industries, and IBCs play a key role in preserving the shelf life of various liquids and products. Their protective design shields contents from harmful external factors, such as moisture, UV rays, and temperature fluctuations. This is particularly important for sensitive products like chemicals, pharmaceuticals, and certain food items. The airtight and light-resistant features of IBCs help maintain product integrity over time, ensuring that they remain effective and safe until they reach the end-user. Businesses benefit from reduced spoilage and waste, leading to better resource utilization and customer satisfaction.

Better Inventory Management

Effective inventory management is essential for smooth business operations. IBCs contribute significantly to this aspect by offering uniformity in size and shape, which simplifies stock tracking and management. Their stackable nature allows for efficient organization of storage spaces, making it easier to perform inventory checks and rotations. This uniformity and ease of storage ensure better visibility of stock levels, helping businesses avoid overstocking or stockouts. By enhancing inventory management, IBCs support optimal operational flow and resource planning.

IBC Tote Rentals

For businesses seeking flexibility in their storage and transportation solutions, IBC tote rentals offer a practical option. Renting IBCs is ideal for companies with fluctuating storage needs or those undertaking long- or short-term projects. Furthermore, it eliminates the need for a large initial investment, allowing businesses to manage their finances more effectively. Partnering with a reliable intermediate bulk container supplier for rentals provides access to high-quality IBCs tailored to specific project requirements. This adaptability is especially beneficial for businesses that are expanding into new markets or ramping up production.

Now that you know the 12 reasons for using intermediate bulk containers, it’s evident they are more than just a storage and transportation solution. These containers offer a combination of cost efficiency, safety, sustainability, and operational effectiveness, making them a valuable asset in a wide range of industries. Utilizing IBCs can significantly enhance your business operations, allowing your company to align with modern demands for efficiency and environmental consciousness.